VMC850B CNC Milling umshini, mpo umshini isikhungo

Izici Zomkhiqizo

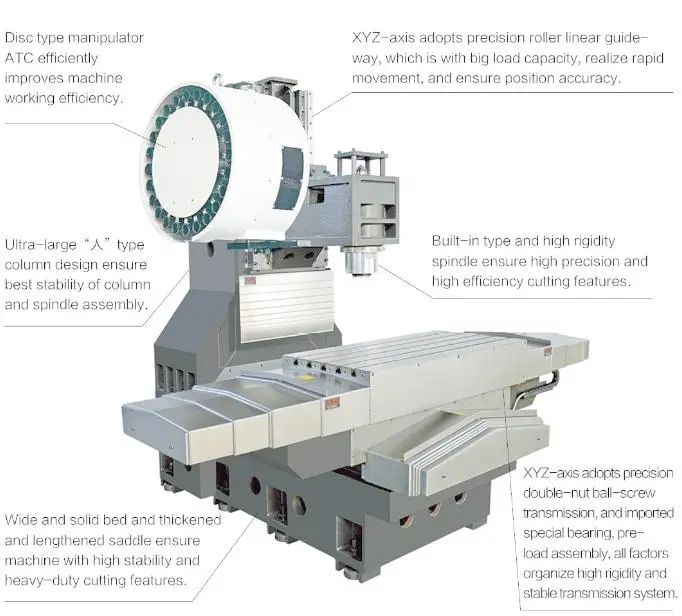

1.Iziyalezo sezizonke

Lo mshini uklanywe ngesakhiwo sozimele esime mpo. Ikholomu igxunyekwe emzimbeni womshini, ibhokisi lokuphotha liyaslayida kukholamu eyenza ukunyakaza kwe-eksisi engu-Z, amaslayidi esihlalo sesihlalo somshini esenza ukunyakaza kwe-eksisi engu-Y, amaslayidi aThandekayo aslayida esihlalweni enza ukunyakaza kwe-eksisi engu-X. Izimbazo ezintathu zonke ziyizikhombandlela ezinejubane eliphezulu lokuphakelayo nokunemba okuphezulu. Sisebenzisa insimbi empunga yekhwalithi ephezulu yomzimba womshini, ikholomu, isihlalo, itafula lokusebenza, ibhokisi lokuphotha elinobuchwepheshe besihlabathi se-resin kanye nokwelashwa kokuguga okuphindwe izikhathi ezi-2 ukuze siqede ukucindezelwa kwensalela kwangaphakathi kwezinto. Lezi zingxenye zonke zilungiselelwe isoftware yeSolidWorks, ethuthukisa ukuqina nokuzinza hhayi kulezi zingxenye kuphela kodwa nomshini. Futhi izovimbela ukuguqulwa nokudlidliza okubangelwa ukusika. Izingxenye ezibalulekile zonke zingeniswa kumkhiqizo odumile emhlabeni wonke ukwenza umshini ube nokuzinza okuphezulu nokuqina. Lo mshini ungafeza inqubo yokugaya, ukumba, ukuphinda kwenziwe kabusha, kuyisicefe, ukubuyisela kabusha, ukuthepha futhi kuvame ukusetshenziselwa iMilitary, izimayini, izimoto, isikhunta, izinsimbi nezinye izimboni zokucubungula imishini. Ingasetshenziselwa zonke izinhlobo zokunemba okuphezulu kanye namamodeli amaningi wenqubo. Ilungele ukukhiqizwa okuncane naphakathi nendawo, okuhlukahlukene, futhi ingafaka emgqeni wokukhiqiza othomathikhi.

2.Isistimu yezimbazo ezintathu

Izimbazo ezintathu zonke ziyizikhombandlela futhi zinedizayini enkulu ye-span yokunemba okuhlala isikhathi eside. Amamotho wama-ax angu-3 axhunywe ngokuqondile ngesikulufu sebhola esinembayo ngaphandle kokuhlanganisa igebe. Isikulufu sebhola ngasinye sama-axes angu-3 singeniswa sisuka kusikulufa sebhola esixhumene ngokunemba esingu-angular namabheringi aphrofeshinali afaniswayo, futhi sizokwenza ukucindezela kwangaphambili kwezikulufu zebhola ukuze zibe nokunemba okuphezulu nokunemba.I-Z-axis servo motor inomsebenzi wamabhuleki ozenzakalelayo. Endabeni yokuphelelwa amandla, i-motor brake ingabanjwa ngokuzenzakalelayo yi-brake ukuyivimbela ukuthi ingajiki, okudlala indima ekuvikeleni ukuphepha.

3.Iyunithi yokuphotha

I-Spindle ikhiqizwa umkhiqizi ochwepheshe ukuze kuqinisekiswe ukunemba okuphezulu nokuqina. I-Spindle bearing ivela kumkhiqizo odumile emhlabeni wonke onembayo wokunemba okuphezulu, futhi ihlanganiswe esimweni sokushisa okungaguquki futhi akukho luthuli. Ngemuva kwalokho, wonke ama-spindles azokwenza ukuhlolwa kwebhalansi eguquguqukayo ukuze aqinisekise ubude bempilo kanye nokuthembeka.Ifakwe uhlelo lokuvikela umjikelezo womoya onengcindezi ephansi, ivuthela umoya ophansi we-spindle esikhaleni esingaphakathi okwenza ungqimba lokuvikela umoya ukuvimbela uthuli, ukupholisa phakathi. intambo yokuphotha. Kulesi simo, ukuphotha okuphothayo kuzosebenza ngaphansi kokungangcoli kwendawo, okuzovikela iyunithi yokuphotha kanye nempilo ende yokuphotha. Isivinini sokuphotha asikwazi ukushintshwa phakathi kwebanga lejubane lokuphotha, elilawulwa yi-motor yangaphakathi encode ukuze libe nomsebenzi wokuma kwe-spindle kanye nokuthepha okuqinile.

4.Isistimu yokuguqula ithuluzi

Umthamo wemagazini wethuluzi ojwayelekile walo mshini ungu-24T futhi uhlanganiswe kukholamu eseceleni. Uma ishintsha ithuluzi, i-tool plate drive futhi ibekwe ngendlela ye-motor drive hobbing cam, ngemva kokuba i-spindle ifika endaweni yokushintsha kwethuluzi, i-ATC izofeza ushintsho lwamathuluzi futhi ithumele isenzo sethuluzi. I-ATC iwumshini we-hobbing cam futhi yenza i-pre-tension bese ikwazi ukuzungezisa ngesivinini esikhulu, okungcono ekushintsheni kwamathuluzi asheshayo nalungile.

5.Isistimu epholile

Lo mshini ufakwe iphampu yokupholisa amanzi egeleza eqondile kanye nethangi lamanzi elinomthamo omkhulu. Isivinini sepompo yokupholisa singu-2m³/h ukuze wenze isiqiniseko sokupholisa okwanele kokubuyisela kabusha. Kukhona umlomo wombhobho wokupholisa endaweni yokuphela kwebhokisi lokuphotha, engenza isipholile komoya kanye nesipholile samanzi ethuluzi nezingcezu zomsebenzi. Ifakwe isibhamu somoya ukuhlanza umshini nezingcezu zokusebenza.

6.Isistimu ye-pneumatic

Iyunithi ye-pneumatic ingahlunga ukungcola kanye nomswakama emthonjeni wegesi ukugwema umonakalo nokuguguleka kwezingxenye zomshini. Iyunithi ye-valve ye-Solenoid ilawula uhlelo nge-PLC ukuze kuqinisekiswe ukuthi izenzo zethuluzi lokuhlanganisa ophothayo, ukuvunguza kwesikhungo sokuphotha, ithuluzi lokugoqa ukuphotha nokupholisa umoya okuphotha kungenziwa ngokushesha nangokwelungile. Ngaso sonke isikhathi ithuluzi lokushintsha ukuphotha, umoya ocindezelwe ocacile uzovunguza usuka esikhungweni sokuphotha ukuze uhlanze imbobo engaphakathi yokuphotha kanye nomphini wethuluzi ukuze kuqiniswe okuphezulu kwenhlanganisela ne-spindle kanye nethuluzi. Izokwandisa ubude bempilo yokuphotha.

7.Ukuvikelwa komshini

Sisebenzisa isivikelo sokuvikela esijwayelekile emshinini, ongagcini nje ngokuvikela i-splash epholile kodwa nokusebenza kokuphepha. Wonke umzila wesitimela ufakwe isivikelo sokuvikela ukuvimbela into epholisayo nesinqandayo endaweni engaphakathi futhi wehlise ukugqokwa nokuguguleka kwe-guideway nesikulufu sebhola.

8.Isistimu yokugcoba

I-Guideway nesikulufu sebhola kufakwe isistimu yokuthambisa emaphakathi kanye nesihlukanisi sikawoyela wevolumu ku-node ngayinye, esingahlinzeka ngamafutha ngamanani anqunyiwe nangezikhathi ukuze kuqinisekiswe ukuthi ubuso besilayidi bugcotshiwe futhi wenziwe kancane. Izothuthukisa ukunemba kanye nempilo ende yesikulufu sebhola nomhlahlandlela.

9.Chip uhlelo lokuthutha

Sinikeza idivayisi ejwayelekile ye-chip remover esebenza kalula. Futhi ungakhetha uhlobo lwe-screw chip conveyor noma uhlobo lwehinge.

| Into | Iyunithi | I-VMC640L | I-VMC640LH | I-VMC850L | I-VMC1000L |

| Ithebula lokusebenza | |||||

| Usayizi osebenzayo | mm | 400×900 | 400×900 | 500×1000 | 500×1200 |

| T-slot (N×W×D) | mm | 3×18×100 | 3×18×100 | 5×18×100 | 5×18×100 |

| Ukuhamba | |||||

| Uhambo lwe-X eksisi | mm | 640 | 640 | 850 | 1000 |

| Uhambo lwe-Y eksisi | mm | 400 | 400 | 500 | 500 |

| Z ukuhamba eksisi | mm | 400 | 500 | 600 | 600 |

| Ibanga lomshini | |||||

| Ibanga ukusuka enkabeni yokuphotha ukuya ekholomu ngaphambili | mm | 440 | 476 | 572 | 572 |

| Ibanga ukusuka ekupheleni kokuphotha kuya etafuleni lomsebenzi | mm | 120-520 | 120-620 | 120-720 | 120-720 |

| Ubukhulu bomshini | |||||

| L×W×H | mm | 2200×2100×2500 | 2200×2100×2550 | 2540×2320×2780 | 3080×2320×2780 |

| Isisindo somshini | |||||

| Ubukhulu. ukuthwala umthwalo we-worktable | kg | 350 | 350 | 500 | 600 |

| Isisindo somshini | kg | 3900 | 4100 | 5200 | 5600 |

| I-spindle | |||||

| I-spindle hole taper | I-BT40 | I-BT40 | I-BT40 | I-BT40 | |

| Amandla e-spindle | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Ubukhulu. isivinini sokuphotha | rpm | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Okuphakelayo(direct drive) | |||||

| Ubukhulu. isivinini sokuphakelayo | Mm/min | 10000 | 12000 | 12000 | 12000 |

| Isivinini sokuphakelayo esisheshayo (X/Y/Z) | m/min | 20/20/10 | 30/30/24 | 32/32/30 | 32/32/30 |

| Isikulufu sebhola (ububanzi + umthofu) | |||||

| Isikulufu sebhola se-X eksisi | 3210 | 3212 | 4016 | 4016 | |

| Isikulufu sebhola le-eksisi engu-Y | 3210 | 3212 | 4016 | 4016 | |

| I-screw yebhola le-axis | 3210 | 4012 | 4016 | 4016 | |

| Ithuluzi Magazine | |||||

| Amandla omagazini wethuluzi | T | 16 | 16 | 24 | 24 |

| Isikhathi sokushintsha ithuluzi | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Ukunemba kokuma (Izinga likazwelonke) | |||||

| Ukunemba kokuma (X/Y/Z) | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Ukunemba kokubeka kabusha (X/Y/Z) | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| CHA. | Igama | Ibhrendi |

| 1 | Uhlelo lwe-CNC | I-Seimens 808D SYSTEM |

| 2 | Injini eyinhloko | Isethi ephelele ye-Siemens drive kuhlanganise ne-servo motor |

| 3 | X/Y/Z eksisi motor, umshayeli | Ama-Seimens |

| 4 | I-Ballscrew | I-Hiwin noma i-PMI (Taiwan) |

| 5 | I-Ballscrew bearing | I-NSK (Japan) |

| 6 | Iziqondiso zomugqa | I-Hiwin noma i-PMI (Taiwan) |

| 7 | I-spindle motor | I-POSA/ROYAL (Taiwan) |

| 8 | Isishintshi sokushisa | I-Taipin/Tongfei (Joint-venture) |

| 9 | Izingxenye eziyinhloko zesistimu yokugcoba | I-Proton (Ibhizinisi elihlangene) |

| 10 | Izingxenye eziyinhloko zesistimu ye-pneumatic | I-AirTAC (Taiwan) |

| 11 | Izingxenye eziyinhloko zesistimu kagesi | I-Schneider (France) |

| 12 | Iphampu lamanzi | China |